Whilst team fc endeavour to continually invest In the latest and most efficient equipment available, it is our team who provide innovation, knowledge, experience and expertise to deliver specialist finishing solutions which dovetail with our customers’ capabilities and requirements

The Iberica JR-105 can die-cut & emboss various materials including paper, cardboard, fluted, plastic and corrugated sheets. The Die-Cutter enables us to offer the complete picture when it comes to a specialist finishing service, since we can also continue to offer window patching, nesting and glued work all in house. Furthermore, the Iberica also comes with an automatic stripping unit, meaning that any designs which include apertures can be easily stripped.

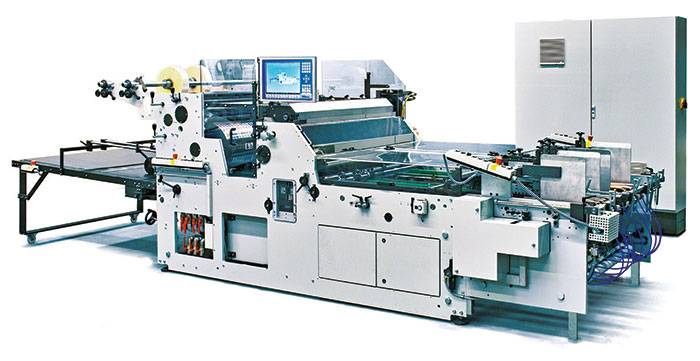

The Heiber + Schroder, Rotary Window Patching and Carton Lining Machine, the 1100 Master, provides the most complete and efficient window patching capability in the marketplace.

The Master feeder is the ultimate answer to a great variety of carton blank profiles for the packaging industry. Make-ready is enhanced by an intelligent operating panel, with integrated video support.

It allows different run modes to achieve optimum speed with minimum marking.

Automatic friction control also allows Integrated Compensation for the changing friction which ensures a smooth feeder operation.

Patented mono-belt vacuum transport behind squaring chains for the highest and unrivalled accuracy in patching, with missing window detection with a marking device.

Maintenance-free and in-built vacuum system, with no vacuum channels, no vacuum tubes and no filters required for blank transfer.

Doctor blade glue system with movable side scrapers, fully splash guarded with cleaning system.

The digital input of blank length, blank width, window length and window position offers a fully guided set-up of the machine. All components in running direction are set automatically.

An Integrated diagnostic program allows control of all drives, motors and sensors.

All data can be stored under product name to maximise efficiencies in set up with 1, 2, 3, 4 up, operation available.

All parts which may be in contact with film or carton inside meet or improve upon the regulations for the production of food packaging.

We also have a second Heiber and Schröder 1100 Window Patcher.

All three of these machines are able to apply flexible windows from a reel, using polyester or acetate film, or susceptor material, in a process commonly referred to as window patching.

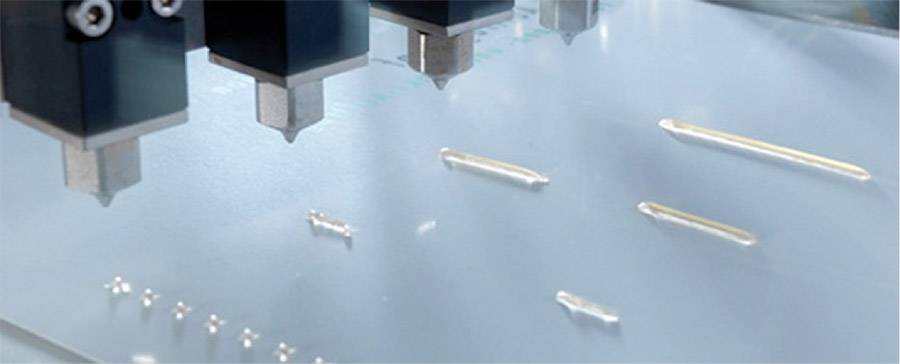

The DigiStar WPPP is a multi-functional automatic window application systems unit which cuts film in line from roll and places pre-creased / die cut plastic windows onto finished carton blanks using a highly bespoke and electronic pre-programmed management system, encompassing a very tactile pick and place movement process incorporating a cold glue stencil application unit, if required two windows can be placed in line in one operation.

With unlimited design possibilities, the carton can incorporate any shape as the window is placed on the inside – meaning glue points and bleeds are discretely hidden, ideal for seamless, luxury packaging.

To monitor the accuracy and general running of the WPPP, an interactive touch screen presents statistics of the job and notifies the operator of any mechanical mal-functions. The tactile device stores details of all productions made, allowing automatic adjustment of the machine for repeat runs.

Whilst performing with utmost accuracy, the WPPP also has the ability to produce tri-fold cartons – an increasingly popular aesthetic device seen more often in up-market or luxury packaging. Cartons are fed into the machine in a normal fashion, but the machine will then pre-split the carton, insert a full window between and eventually glue it. The result is a four panel window which effectively show cases the product – presented beautifully in 360-degree angles, unlike most other packaging designs.

For further information on: Pick and Place

The CE-1000-2 Tray Former is the latest tray former available in the market place today.

Our Heiber + Schröder machines deliver the ideal combination of perfect nested tray / tray forming + clam shell, with superb productivity. These machine give the opportunity to create a wide range of products; enabling our customers’ to diversify into specialist markets or produce standard products with greater efficiency

When we installed our Heiber and Schröder CE1000 nested tray forming machine, which is equipped to run twin stream, our innovation team set about developing modifications that have comprehensively changed the running capability and flexibility of what we can finish to perfectly dovetail with our customers’ requirements. However we have been surprised at the speed and demand for change from the plastic option to cardboard, paper based biodegradable products

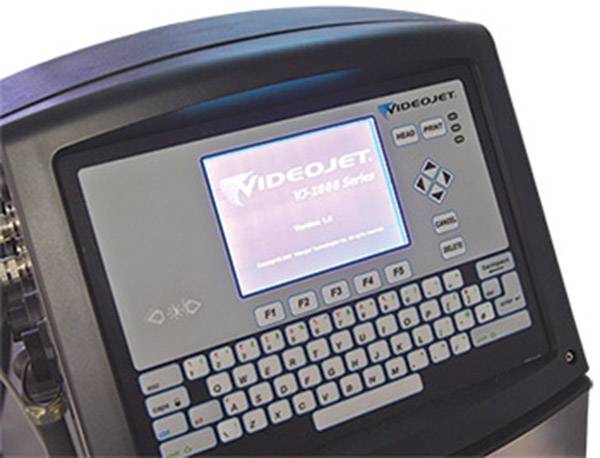

The Videojet 1520 printer is a highly flexible platform that has been specifically designed for medium-duty coding applications. Its advanced features make it a benchmark performer that can add that little bit extra to various cartons. It can be used to print dates, numbers, initials and promotional materials in up to 26 different languages. In addition to running promotions, inline inkjet printing is a great way to ensure the traceability of cartons.

The Videojet 1520 printer is a highly flexible platform that has been specifically designed for medium-duty coding applications. Its advanced features make it a benchmark performer that can add that little bit extra to various cartons. It can be used to print dates, numbers, initials and promotional materials in up to 26 different languages. In addition to running promotions, inline inkjet printing is a great way to ensure the traceability of cartons.

Its versatility also means that it can be used in conjunction with our many other capabilities, such as die-cutting, window patching, pick and place, carton nesting, gluing, and much more. The Smart Cartridge fluid delivery system is able to eliminate spills and help ensure the correct fluids are being used.

![]()

Omega x 3

The Omega All-Pro gluers produce multi-point gluing, straight line, crash lock, integral fitment, 4 corner & 6 Corner gluing (with single finger servo fold for high speed precision) as well as double wall, Z fold, and CD sleeves at a maximum speed of 400 m/min. We are able to glue a wide range of substrates from carton board to corrugated.

When you add our Omega SM 110 we have a truly extensive range and versatility within our gluing capability

Vega-750

Our Vega-750 Folder Gluer is capable of producing, straight line, crash lock and a multitude of other designs. The versatility of the Vega-750 enables us to work with greater precision on smaller cartons, including collarattes (bottle collars). As well as our Omega All-Pro Gluers, the Vega-750 is capable of finishing a wide range of substrates, F/B/B to corrugated.

Our Omega All-Pro gluing machines feature up to 32 cold glue applicators, allowing us to offer multi-point gluing capabilities for any carton design.

Realising that sometimes a job requires different adhesive applications to effectively glue complex products, we have recently invested in a Robatech hot melt glue applicator. This has enabled us to offer our customers hot melt, and peelable glue systems for some of the more difficult materials to glue.

StraPack SQ-800 Automatic Strapper

StraPack SQ-800 Automatic Strapper

The StraPack SQ-800 is the latest generation automatic strapping machine from StraPack. It features more efficient Brushless DC motors, adjustable table height, a cycle counter and foot bar.

Key features:

- Up to 54 straps per minute (even with full tension applied: tension capability up to 450N (45.9kgf)

- Ready to operate in under 25 seconds

- Simple controls and foot bar for faster, two-handed operation

- Adjustable Table Height, 8 positions (see zoomed in picture)

- Brushless DC Motors = Less Moving Parts, Less Noise, Less Strap Dust and 20% more efficient than AC Motors

- Self-correcting technology in the unlikely event of a short feed

- Easy strap loading and automatic re-feed

- Easy maintenance and cycle counter to help plan service schedule

- Table plates hinged for easy access

- Portable, Robust construction

Team FC have a number of strappers available to ensure fast, efficient completion of the specific finishing process.

Our Pallet wrapper provides durable, stretchy and protective wrapping that’s ideal for use in warehouses and shipping or storage areas. It’s primarily intended to keep products intact when they’re stored and shipped on pallets, but also offers a smooth surface for labelling and attaching documentation as part of the consignment.